The name of Louis Comfort Tiffany is nearly synonymous with American Art Nouveau glass. His artistry, technical innovation, and business acumen combined to make him a leader in the world of art glass – frequently imitated but never equaled. Certainly best known for windows and lamps, Tiffany’s glassworks produced a wide variety of decorative pieces. Time has been kind to Tiffany; the glass prized in its own day has become a particular favorite among collectors.

Louis was the son of Charles Lewis Tiffany the founder of jewelry giant Tiffany & Co. Louis was expected to follow his father into the jewelry trade, but as we know he took a different path entirely. In his book American Art Nouveau Glass, Albert Christian Revi writes that young Tiffany was “A nonconformist, individualistic, exacting and autocratic, determined to be the best and greatly talented, he was a romantic always in his quest for beauty.”

Louis was the son of Charles Lewis Tiffany the founder of jewelry giant Tiffany & Co. Louis was expected to follow his father into the jewelry trade, but as we know he took a different path entirely. In his book American Art Nouveau Glass, Albert Christian Revi writes that young Tiffany was “A nonconformist, individualistic, exacting and autocratic, determined to be the best and greatly talented, he was a romantic always in his quest for beauty.”

It is, perhaps, this combination of personality traits that led Tiffany to pursue art. He studied painting for a year in Paris and was made an associate at the National Academy of Design in 1871. He achieved full Academician status there in 1880, at which point he turned to the applied arts and worked as a decorator. He produced many stunning interiors during his time decorating. Among his clients were legendary names such as the Vanderbilts and Goelets. President Chester Arthur commissioned Tiffany to redecorate the White House during his term and to decorate and furnish his summer home.

It appears that Tiffany’s passion for glass emerged over a period of time. His European studies and travels exposed him to a variety of approaches to the craft and he is known to have been inspired by ancient and medieval glass techniques. As an interior designer he of course used glass extensively and was creating glass accessories for his clients.

The first recorded association with Tiffany and a glassworks was the establishment of The Tiffany Glass Company on December 1, 1885. There is reasonable speculation that Tiffany was involved in glass manufacture somewhat earlier. In the 1943 publication of Antiques it was reported that Tiffany had been involved in glassworks as early as 1878, but there is no concrete evidence of this.

On February 18, 1892 a new company was formed called the Tiffany Glass & Decorating Company. The stated purpose of this company was the “manufacture and sale of glass, decorative objects and materials of all descriptions, and the applying of these materials to buildings and other structures: also the manufacture and sale of furniture, house and church fittings of all kinds, and the conducting of a general decorating business and all things incident thereto.” Clearly ambitions for the Tiffany Glass & Decorating Company were high, and according to stockholder records this company was unsuccessful.

Finally the Stourbridge Glass Company was incorporated on April 7, 1893. In the first incorporation of this company Tiffany’s name did not appear, perhaps due to his two failures previously. After 6 months of success, on September 13, 1893, Tiffany’s name started appearing in the company documents where he was named as president.

Stourbridge Glass Company was much more successful than the previous efforts and on September 29, 1902 the name of the corporation was changed to Tiffany Furnaces with Tiffany on record as holding the majority of the stock of the company.

There are many factors that contributed to the success of the Tiffany Furnaces. Louis Tiffany’s persistence certainly helped, as did his artistic vision. In addition, the skills of the people who worked with him should be given credit. The Nashes, with whom he ran his furnaces, developed advanced glass techniques that allowed Tiffany a much broader range for his expression.

Tiffany was an ambitious, talented and persistent business owner and artist. He had grand visions about what he wanted to accomplish and accomplished most them. There are many different styles of Tiffany glass. Here we look at the different styles, how they were made, and what they looked like.

Tiffany and Nash were not the first to produce lustred glass. Tiffany’s 1881 patent notes that lustering was a “process well known to glass manufacturers.” However, the earliest examples of lustered wares had a mirror-like finish and not the soft sheen that is associated with Art Nouveau Glassware. Arthur J. Nash is responsible for developing the lustre for glassware that resembled the nacreous (resembling mother-of-pearl) finish found on ancient glass that had been exposed to corrosive elements. This type of lustre took several years to develop.

When Tiffany first introduced lustered glass to the marketplace his shop used the technique sparingly. As demand grew more pieces were produced and the lustering process was used more extensively on individual pieces. There were several types of lustred glassware produces by Tiffany and Nash:

When Tiffany referred to his Agate glass he said that it was “glass of a chemically reactive character.” It was produced by combining several different colored opaque glasses into one pot and stirring them until they became striated. Chemically reactive glasses then were combined with these non-reactive glasses which produced a laminated effect throughout the metal. This type of glass had to be worked quickly and at a low temperature in order to retain the beauty of the glass. If the heat was too high or the work took too long the glass would turn dark.

Agate glass was usually polished or carved exposing more of the laminated structure. Occasionally, Agate glass was used to plate crystal or colored glass. The Agate glass was then cut away to show the transparent glass underneath. Some of Tiffany’s Agate wares are also called “Metallic Glass.” The Metallic Glass designation is for the pieces that are reddish brown and heavily lustred.

Tiffany long dreamed of producing copies of ancient glass objects. By teaming up with the technical brilliance of Arthur J. Nash he was able to make this happen. The terms Antique and Cypriote glass are applied to the Tiffany glass wares that have a corroded and nacreous texture.

While the Cypriote label is sometimes used for other styles it is most consistently applied to a style of glassware that is finely pitted and has a weathered surface. These pieces are often intentionally slightly out of round or uneven, which gives them a very aged appearance. The Cypriote pieces were made by rolling transparent yellow glass over crushed glass bits on a marver – the flat iron or marble surface used in glass craft. This process created a crusty appearance that was then heavily lustred, resulting in a very good imitation of ancient weathered glass. It is believed that Tiffany brought antique pieces to his factory for his workers to copy exactly.

Lava glass, which was originally called Volcanic glass, was made by adding pieces of basalt or talc to the glass melts. The resulting pieces were decorated with gold lustre glass. As the name implies these pieces were designed to resemble volcanic eruptions. Lava glass is intentionally misshapen and rarely symmetrical. The form is organic. These pieces are quite beautiful, but in a way not generally associated with Tiffany’s glass works.

Reactive glass was made from sensitive glass that changed color when reheated and the name is applied to all Tiffany glasses that changed in response to temperature. This type of glass is very representative of what Art Nouveau was at its best.

Morning Glory is a type of reactive glass that is made with a base of celadon colored glass. This base was then decorated with vines and leaves and small round patches of opalescent gold-ruby glass that would become the flowers. When the object was reheated these patches transformed into various shades of blue, purple, and red – all of which were opalescent. Some pieces were also internally lustred creating the coveted “under-the-water” effect.

Also included in this technique are the Opalescent Optic, Rainbow, and Flashed Glass types. Rainbow glass was made by adding uranium impregnated metal. During the reheating process an opalescent effect was brought out in the finished article. Flashed Glass, which is also referred to as Pastel Tiffany, led to one of the only disagreements on record between Nash and Tiffany. It was a highly commercial product and Tiffany thought it too much so. Flashed Glass was created by partially plating a foundation of sensitive glass with colored glass. This type of glassware was made in an variety of styles.

No matter what the type of glass it was – Agate, lustred, crystal, or tinted – if a glass piece had been cut or engraved it was referred to as carved. Tiffany employed only the best engravers and artisans at his factory and they spent much time working on the glass wares. There were many pieces produced by the Tiffany shops that took hundreds of man hours each to carve, but not all did. Some of the lighter carvings were done to salvage imperfect pieces and make them saleable.

Aquamarine glass was made in two types and produced mainly in 1913. One style featured pond life, and the other marine. These pieces were very heavy and were made of light green glass meant to simulate sea water. Because it was difficult to produce, there were very few pieces of this type of glass made.

It is very common for glassmakers at some point in their careers to use ancient glass techniques originally developed in Venice. Tiffany was no exception. He used millefiori rods to simulate coral and aquatic plants and animals in his Aquamarine glass.

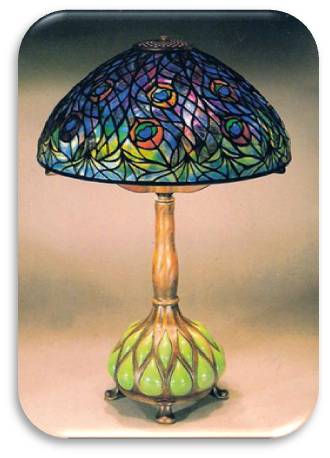

As we have seen, Tiffany’s company produced many fine examples of beautiful glassware, but he is most famous for is his work with windows and lamps. This is a style that has been greatly copied over the years and genuine Tiffany lamps are greatly sought by collectors. Tiffany was inspired in his design by studying ancient cathedrals in much of Europe where he acquired a small, ancient stain glassed window. Tiffany learned all he could about the construction and joining of the glass from this study. He then improved on the techniques and in true Tiffany style, patented them on February 8, 1881.

Before Tiffany owned his own glass factory, he purchased the glass he needed to make these windows and shades from Louis Heidt in Brooklyn, New York. He primarily purchased two types of glass. The first type was called cathedral and was colored or opalescent. The second type was called drapery and mimicked the patterns and folds in draperies and clothing.

At the workshop, the workers tried to match Tiffany’s drawings as exactly as possible. But this was not always feasible because the exact colors that Tiffany wanted were not obtainable. Trouble obtaining the desired colors was one of the factors that drove Tiffany to open his glass factory. Tiffany’s workshop was masterful at producing unique joinery for the glassworks. They developed these techniques to be able to execute Tiffany’s visions and have more control over the design. At the time, glass was generally cut to conform to the lead. In Tiffany’s shop, the lead was worked to conform to the glass. This may seem like a subtle difference, but it allowed a great deal more control of the designs.

Tiffany shades were made in the same way as the windows, with a lead frame being added as they developed the technique. One of the more remarkable features of Tiffany shades are the flowing, unbroken lines of the leading, an effect that Tiffany’s contemporaries could not duplicate. Tiffany made many different styles of lamps for many uses. He is famous for using dragonfly and nautilus motifs on his leaded lamps, but lamps were also made of solid pieces of lustered glass.

Tiffany lamps are a favorite of collectors the world over due to their quality, beauty, and unsurpassed artistic value.

Tiffany Glass was stored unmarked in their stockroom until it went out to various outlets to be sold. Before the glass left the factory it was sent to the Cutting Department where it was marked with a combination of signature, letters, and numerals.

Most glassware was signed with initials, but fine art pieces received a full signature. The numbers were the stock numbers of the piece and the letters represented the outlet where the piece was being sold. Occasionally a piece will have two different sets of letter and number marks, indicating the piece was sent to two different outlets before it was sold.

Numbers were assigned in sequential order determined by when the piece was shipped. Therefore, if a piece was in stock for a period of time the number it was given will not be related to other similar pieces. Because of this methodology dates are sometimes hard to determine for Tiffany glassware. Tiffany maintained a high degree of control over his glassware and his pieces were sold on consignment only. If a piece did not sell at full retail price within three months it was returned to the factory. If after be available at three outlets it did not sell, the work was sold to an employee at a discount, given to a friend, or destroyed. Imagine how many Tiffany wares may have been destroyed because they didn’t sell!

American Art Nouveau Glass - The Steuben Glass Works

In the first decades of the 20th century, the Steuben Glass Works produced some of the great collectibles of the American interpretation of Art Nouveau. The early Steuben design styles are associated with Frederick Carder an artist and glassmaker who led the firm between 1903 and 1932. Typically referred to as the Carder Period, the colorful wares that Steuben produced in this time are very distinct from later Steuben pieces and are now highly prized by collectors.

Collecting Carnival Glass

An inexpensive, mass produced imitation of a popular art glass style, these pieces were often given away as prizes and premiums during the early years of the 20th century and it is from this legacy that the term carnival glass is derived. It is imbued with an iridescent sheen which reflects light and gives the glass a shimmer with a metallic tinge.

Pirated Glassware that Collectors Want to Own

The 1996 discovery of what is believed to be the wreckage of Blackbeard’s ship Queen Anne’s Revenge, is providing historians and collectors new information about the fragile and transparent objects that came onto the North American Continent before arrival of the first piece of cut glass.

Carnival Glass Value Guide

Prices for a wide range of collectible vintage and modern carnival glass.

Depression Glass Value Guide

Prices for a wide range of manufacturers, patterns and colors of collectible depression glass.

Collecting Antique Glass

Valuable tips for new and experienced collectors alike on such topics as what collectors value, how to care for glass, and how to spot fakes and forgeries.

Glass – A Collector’s Guide to the History and Craft

Throughout much of history glass has been a precious commodity; as valuable as gemstones, sought by the wealthy and powerful, and the secrets of its manufacture closely guarded. This overview for collectors provides valuable insight how glass is made and important milestones in the history of the craft.

The Jewelry of Rene Lalique

In the late 1800’s, Rene Lalique burst onto the jewelry-making scene at the perfect time; his vision, his imagination, and his creative flair were a perfect complement to the spirit of the Art Nouveau movement, and by the turn of the century Lalique had established himself as a dominant force in the Art Nouveau style of jewelry design.

The Charm of Victorian Jewelry

From draping necklaces of glittering garnets, to sweet, sentimental seed pearl lockets, Victorian jewelry continues to charm collectors and jewelry buyers with a sentimental streak. The jewelry of this time is romantic, sentimental and often steeped in symbolism, with fashions evolving rapidly as industrialization simultaneously influenced both the manufacture of jewelry and the societal roles of men and women.